+86 15814116500

+86 15814116500 | Availability: | |

|---|---|

| Quantity: | |

PEC2005A

COSO

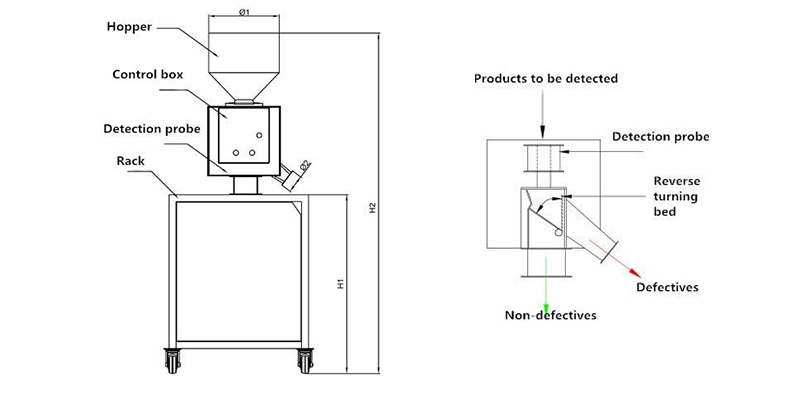

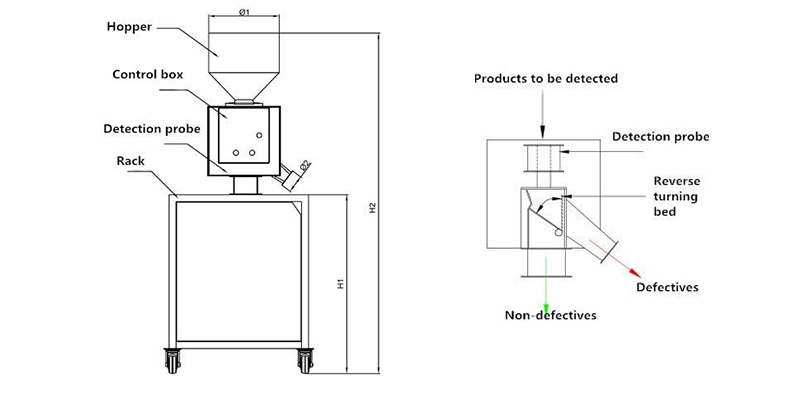

The Industrial Throat Pipeline Metal Detector Separator Easy Installation is a specialized inline inspection system designed for detecting and removing metal contaminants in pneumatic or gravity-fed material pipelines. This innovative solution combines high-sensitivity metal detection with automatic separation functionality in a compact design that can be installed in under 2 hours with minimal production downtime .

Featuring a 32mm to 100mm diameter pipeline range and operating pressure up to 0.7MPa, this detector accommodates various material flow rates common in food processing, pharmaceutical, and chemical industries . Its advanced coil design and digital signal processing achieve detection sensitivity of 0.5mm for ferrous metals and 1.0mm for non-ferrous contaminants in flowing granular or powdered materials .

Constructed with 304 stainless steel contact parts and IP55-rated housing, the system withstands harsh industrial environments including temperature fluctuations from -5°C to 95°C and continuous exposure to dust and moisture . The automatic separation mechanism uses a quick-acting ball valve that diverts contaminated material within 100ms of detection, minimizing product loss while ensuring contaminant removal .

The detector includes a user-friendly control panel with LED status indicators and simple calibration controls, requiring minimal operator training for effective operation .

Modular construction with flanged connections allows installation in 2 hours or less into existing pipelines, reducing production downtime compared to traditional systems requiring extensive modification .

Rated for continuous operation at up to 0.7MPa working pressure with leak-proof seals, suitable for both pneumatic conveying systems and gravity-fed material lines .

Identifies ferrous contaminants as small as 0.5mm and non-ferrous metals down to 1.0mm in flowing materials, including powders, granules, and small particulates .

100ms response time ball valve diversion system isolates contaminated material without stopping material flow, maintaining production continuity with minimal product waste .

304 stainless steel contact surfaces resist corrosion from aggressive materials, while IP55-rated electronics protection ensures reliability in dusty or humid environments .

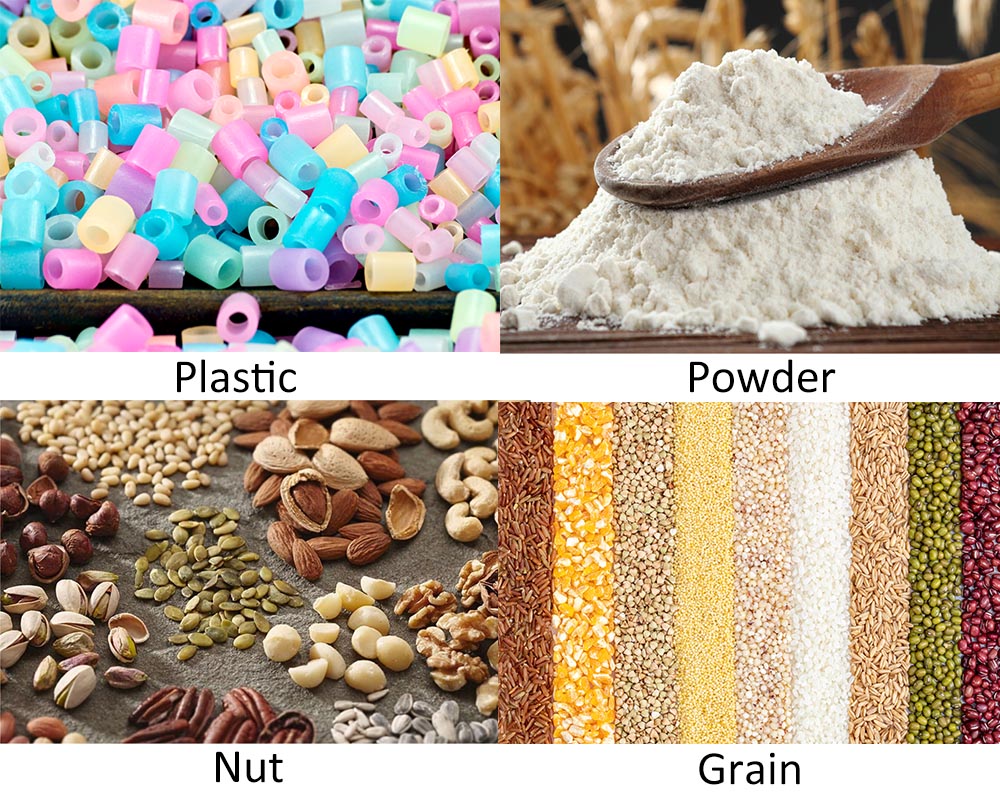

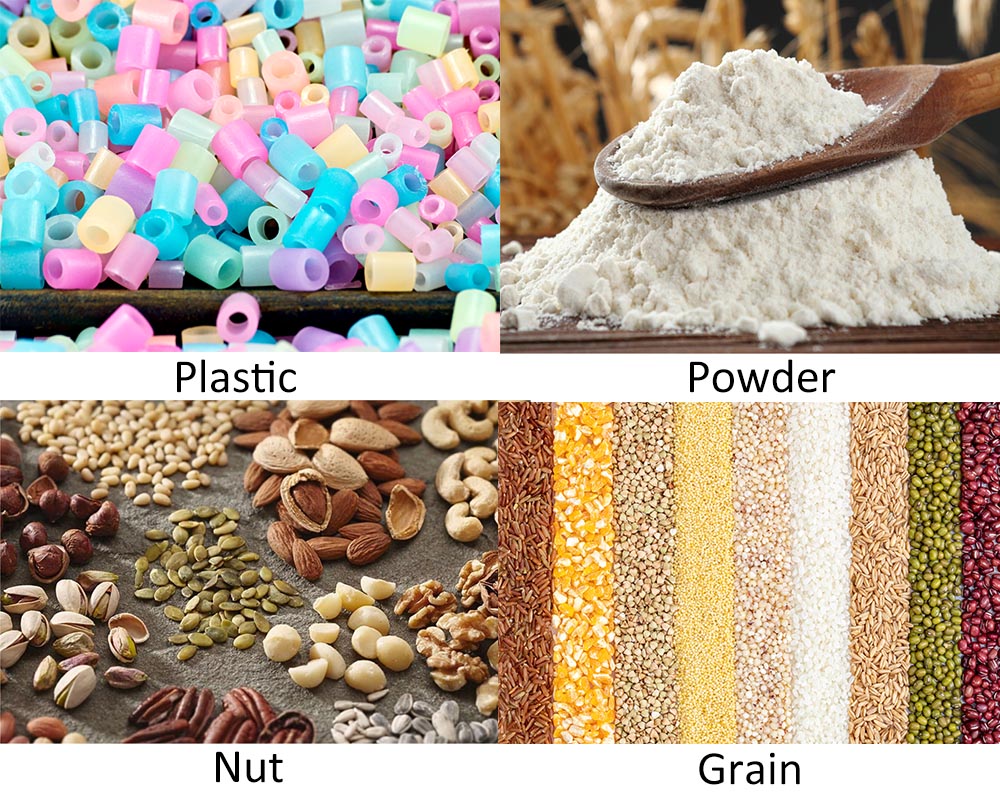

Essential for detecting metal contaminants in flour, sugar, spices, and grain flows, protecting processing equipment and ensuring food safety compliance.

Critical for inspecting active pharmaceutical ingredients (APIs) and excipients in powder form, preventing metal contamination in drug manufacturing processes.

Ideal for monitoring flows of plastic pellets, resin powders, and chemical additives, protecting downstream processing equipment from damage.

Detects metal fragments in seed, fertilizer, and animal feed pipelines, ensuring product purity and preventing equipment damage in milling operations.

The detector features flanged connections that match standard pipeline sizes (32mm to 100mm diameter) and includes all necessary gaskets and hardware. Its compact design fits into existing line configurations with minimal space requirements, allowing installation in under 2 hours by maintenance personnel .

Upon detection, the system activates a quick-acting ball valve within 100ms that diverts the contaminated material stream to a collection chamber. After diversion, the valve automatically resets to normal flow, typically within 2-3 seconds, minimizing production interruption .

Yes, the detector's sensitivity can be adjusted for different material types, including powders, granules, and pellets. Specialized settings account for material density and flow characteristics to maintain detection accuracy while minimizing false alarms .

| Model | Inner Diameter (Ф mm) | Sensitivity | Air Compression | Max Throughput (L/h) | Material Temperature | Defectives Eliminated Time | |

| Fe Ф | SUS Ф | ||||||

| PEC2005A-30 | 20 | 0.3 mm | 0.6 mm | 3~5 Bar | 300 | < 80ºC | 0.3~5s |

| PEC2005A-50 | 40 | 0.5 mm | 1.0 mm | 3~5 Bar | 2000 | < 80ºC | 0.3~5s |

| PEC2005A-70 | 60 | 0.8 mm | 1.2 mm | 3~5 Bar | 5000 | < 80ºC | 0.3~5s |

| PEC2005A-100 | 80 | 1.0 mm | 1.5 mm | 3~5 Bar | 12000 | < 80ºC | 0.3~5s |

| PEC2005A-120 | 100 | 1.2 mm | 2.0 mm | 3~5 Bar | 16000 | < 80ºC | 0.3~5s |

| PEC2005A-150 | 130 | 1.5 mm | 2.5 mm | 3~5 Bar | 25000 | < 80ºC | 0.3~5s |

| PEC2005A-170 | 150 | 2.0 mm | 3.0 mm | 3~5 Bar | 44000 | < 80ºC | 0.3~5s |

The Industrial Throat Pipeline Metal Detector Separator Easy Installation is a specialized inline inspection system designed for detecting and removing metal contaminants in pneumatic or gravity-fed material pipelines. This innovative solution combines high-sensitivity metal detection with automatic separation functionality in a compact design that can be installed in under 2 hours with minimal production downtime .

Featuring a 32mm to 100mm diameter pipeline range and operating pressure up to 0.7MPa, this detector accommodates various material flow rates common in food processing, pharmaceutical, and chemical industries . Its advanced coil design and digital signal processing achieve detection sensitivity of 0.5mm for ferrous metals and 1.0mm for non-ferrous contaminants in flowing granular or powdered materials .

Constructed with 304 stainless steel contact parts and IP55-rated housing, the system withstands harsh industrial environments including temperature fluctuations from -5°C to 95°C and continuous exposure to dust and moisture . The automatic separation mechanism uses a quick-acting ball valve that diverts contaminated material within 100ms of detection, minimizing product loss while ensuring contaminant removal .

The detector includes a user-friendly control panel with LED status indicators and simple calibration controls, requiring minimal operator training for effective operation .

Modular construction with flanged connections allows installation in 2 hours or less into existing pipelines, reducing production downtime compared to traditional systems requiring extensive modification .

Rated for continuous operation at up to 0.7MPa working pressure with leak-proof seals, suitable for both pneumatic conveying systems and gravity-fed material lines .

Identifies ferrous contaminants as small as 0.5mm and non-ferrous metals down to 1.0mm in flowing materials, including powders, granules, and small particulates .

100ms response time ball valve diversion system isolates contaminated material without stopping material flow, maintaining production continuity with minimal product waste .

304 stainless steel contact surfaces resist corrosion from aggressive materials, while IP55-rated electronics protection ensures reliability in dusty or humid environments .

Essential for detecting metal contaminants in flour, sugar, spices, and grain flows, protecting processing equipment and ensuring food safety compliance.

Critical for inspecting active pharmaceutical ingredients (APIs) and excipients in powder form, preventing metal contamination in drug manufacturing processes.

Ideal for monitoring flows of plastic pellets, resin powders, and chemical additives, protecting downstream processing equipment from damage.

Detects metal fragments in seed, fertilizer, and animal feed pipelines, ensuring product purity and preventing equipment damage in milling operations.

The detector features flanged connections that match standard pipeline sizes (32mm to 100mm diameter) and includes all necessary gaskets and hardware. Its compact design fits into existing line configurations with minimal space requirements, allowing installation in under 2 hours by maintenance personnel .

Upon detection, the system activates a quick-acting ball valve within 100ms that diverts the contaminated material stream to a collection chamber. After diversion, the valve automatically resets to normal flow, typically within 2-3 seconds, minimizing production interruption .

Yes, the detector's sensitivity can be adjusted for different material types, including powders, granules, and pellets. Specialized settings account for material density and flow characteristics to maintain detection accuracy while minimizing false alarms .

| Model | Inner Diameter (Ф mm) | Sensitivity | Air Compression | Max Throughput (L/h) | Material Temperature | Defectives Eliminated Time | |

| Fe Ф | SUS Ф | ||||||

| PEC2005A-30 | 20 | 0.3 mm | 0.6 mm | 3~5 Bar | 300 | < 80ºC | 0.3~5s |

| PEC2005A-50 | 40 | 0.5 mm | 1.0 mm | 3~5 Bar | 2000 | < 80ºC | 0.3~5s |

| PEC2005A-70 | 60 | 0.8 mm | 1.2 mm | 3~5 Bar | 5000 | < 80ºC | 0.3~5s |

| PEC2005A-100 | 80 | 1.0 mm | 1.5 mm | 3~5 Bar | 12000 | < 80ºC | 0.3~5s |

| PEC2005A-120 | 100 | 1.2 mm | 2.0 mm | 3~5 Bar | 16000 | < 80ºC | 0.3~5s |

| PEC2005A-150 | 130 | 1.5 mm | 2.5 mm | 3~5 Bar | 25000 | < 80ºC | 0.3~5s |

| PEC2005A-170 | 150 | 2.0 mm | 3.0 mm | 3~5 Bar | 44000 | < 80ºC | 0.3~5s |