+86 15814116500

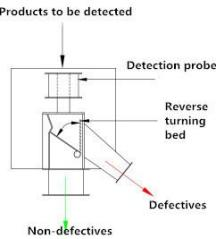

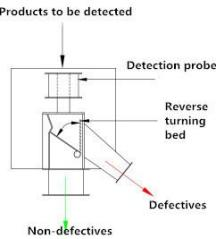

+86 15814116500 PEC2005B economical metal separator adopts German technology.It has high sensitivity and reliability; it is used to separate magnetic and non-magnetic metals from free fall bulk materials and ensure product quality;Integrated metal foreign body rapid elimination system, it’s suitable for testing bulk products.

| Availability: | |

|---|---|

| Quantity: | |

The Throat Convenient Food Metal Separator is a specialized contamination detection system designed for integration into food processing lines, specifically at the "throat" or transition points between processing stages. This compact yet powerful system is engineered to detect and remove metallic contaminants from various food products, ensuring consumer safety and regulatory compliance. Utilizing advanced magnetic induction technology, the separator can identify ferrous, non-ferrous, and stainless steel contaminants as small as 0.8mm in diameter, making it suitable for high-sensitivity applications in food production. The system features an IP69 rating, providing exceptional resistance to high-pressure, high-temperature cleaning regimes essential in food processing environments.

Constructed with food-grade materials and designed according to EHEDG principles, this metal separator meets the strict hygiene standards required in food manufacturing. Its convenient throat design allows for easy integration into existing production lines, particularly in powder, granular, or bulk food processing applications where contaminants can enter the product stream at transition points.

Equipped with advanced sensors and multi-frequency detection technology, the separator can identify even minute metal contaminants, including ferrous metals, non-ferrous metals, and stainless steel, ensuring comprehensive contamination control. The system maintains consistent sensitivity across varying product conditions and temperatures.

The IP69 rating ensures the separator can withstand rigorous cleaning protocols using high-pressure water and steam without compromising performance. All surfaces are designed for easy access and quick cleaning, minimizing downtime between production runs and reducing the risk of bacterial contamination.

Upon detecting a metal contaminant, the system activates an automatic rejection mechanism that removes the contaminated product from the production line. This rapid response prevents contaminated items from proceeding further in the manufacturing process.

The intuitive control panel allows operators to monitor system performance, adjust sensitivity settings, and access diagnostic information. The interface provides clear visual and audible alerts when contaminants are detected, ensuring prompt attention to potential issues.

The throat design enables seamless installation at critical control points in food processing lines, including between mixers, conveyors, and packaging equipment. This strategic placement maximizes contamination detection efficiency at transition points where foreign objects are most likely to enter the product stream.

Ideal for detecting contaminants in flour, sugar, spices, and powdered drink mixes, the separator ensures these fine-particulate products remain free from metal impurities during processing.

The system effectively inspects granular items such as rice, grains, seeds, and dried fruits, protecting consumers from potential metal contaminants that may be introduced during harvesting or processing.

In bakery production, the separator checks dough mixtures, batters, and confectionery ingredients for metal particles that could enter the product from processing equipment.

For convenience foods and pre-packaged meals, the separator provides an additional layer of safety by inspecting ingredients before final packaging, ensuring compliance with food safety regulations.

The Throat Convenient Food Metal Separator can detect ferrous contaminants as small as 0.8mm in diameter and non-ferrous/stainless steel contaminants starting at 1.5mm in diameter, meeting or exceeding FDA guidelines for food safety.

We recommend calibration at least once per month under normal operating conditions. Additional calibrations may be necessary after major cleaning procedures or if product characteristics change significantly.

Yes, the system meets FDA requirements outlined in the Food Safety Modernization Act (FSMA) and adheres to HACCP principles, making it suitable for use in regulated food production environments.

Yes, the system is designed to operate with products at typical food processing temperatures. The detection sensitivity remains consistent across a wide range of product temperatures and moisture levels.

(Special for flakes ) (Special for Power ) (LCD Screen metal Separator)

Model | Dimension (Фmm) | Sensitivity | air compression | Max.throughput(L/h) | Material temperature | Defectives eliminated time | Installation height(mm) | |

FeΦ | SUSΦ | |||||||

PEC2005B-30 | 30 | 0.2mm | 0.4mm | 3~5Bar | 400 | < 80℃ | 0.3~5s | |

PEC2005B-50 | 50 | 0.3mm | 0.6mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s | |

PEC2005B-70 | 70 | 0.7mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s | |

PEC2005B-100 | 100 | 0.8mm | 1.2mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s | 473 |

PEC2005B-120 | 120 | 1.0mm | 1.5mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s | |

PEC2005B-150 | 150 | 1.2mm | 2.0mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s | 600 |

PEC2005B-200 | 200 | 2.0mm | 2.5mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s | 922 |

PEC2005B-250 | 250 | 3.0mm | 3.5mm | 3~5Bar | 69000 | < 80℃ | 0.3~5s | 948 |

The Throat Convenient Food Metal Separator is a specialized contamination detection system designed for integration into food processing lines, specifically at the "throat" or transition points between processing stages. This compact yet powerful system is engineered to detect and remove metallic contaminants from various food products, ensuring consumer safety and regulatory compliance. Utilizing advanced magnetic induction technology, the separator can identify ferrous, non-ferrous, and stainless steel contaminants as small as 0.8mm in diameter, making it suitable for high-sensitivity applications in food production. The system features an IP69 rating, providing exceptional resistance to high-pressure, high-temperature cleaning regimes essential in food processing environments.

Constructed with food-grade materials and designed according to EHEDG principles, this metal separator meets the strict hygiene standards required in food manufacturing. Its convenient throat design allows for easy integration into existing production lines, particularly in powder, granular, or bulk food processing applications where contaminants can enter the product stream at transition points.

Equipped with advanced sensors and multi-frequency detection technology, the separator can identify even minute metal contaminants, including ferrous metals, non-ferrous metals, and stainless steel, ensuring comprehensive contamination control. The system maintains consistent sensitivity across varying product conditions and temperatures.

The IP69 rating ensures the separator can withstand rigorous cleaning protocols using high-pressure water and steam without compromising performance. All surfaces are designed for easy access and quick cleaning, minimizing downtime between production runs and reducing the risk of bacterial contamination.

Upon detecting a metal contaminant, the system activates an automatic rejection mechanism that removes the contaminated product from the production line. This rapid response prevents contaminated items from proceeding further in the manufacturing process.

The intuitive control panel allows operators to monitor system performance, adjust sensitivity settings, and access diagnostic information. The interface provides clear visual and audible alerts when contaminants are detected, ensuring prompt attention to potential issues.

The throat design enables seamless installation at critical control points in food processing lines, including between mixers, conveyors, and packaging equipment. This strategic placement maximizes contamination detection efficiency at transition points where foreign objects are most likely to enter the product stream.

Ideal for detecting contaminants in flour, sugar, spices, and powdered drink mixes, the separator ensures these fine-particulate products remain free from metal impurities during processing.

The system effectively inspects granular items such as rice, grains, seeds, and dried fruits, protecting consumers from potential metal contaminants that may be introduced during harvesting or processing.

In bakery production, the separator checks dough mixtures, batters, and confectionery ingredients for metal particles that could enter the product from processing equipment.

For convenience foods and pre-packaged meals, the separator provides an additional layer of safety by inspecting ingredients before final packaging, ensuring compliance with food safety regulations.

The Throat Convenient Food Metal Separator can detect ferrous contaminants as small as 0.8mm in diameter and non-ferrous/stainless steel contaminants starting at 1.5mm in diameter, meeting or exceeding FDA guidelines for food safety.

We recommend calibration at least once per month under normal operating conditions. Additional calibrations may be necessary after major cleaning procedures or if product characteristics change significantly.

Yes, the system meets FDA requirements outlined in the Food Safety Modernization Act (FSMA) and adheres to HACCP principles, making it suitable for use in regulated food production environments.

Yes, the system is designed to operate with products at typical food processing temperatures. The detection sensitivity remains consistent across a wide range of product temperatures and moisture levels.

(Special for flakes ) (Special for Power ) (LCD Screen metal Separator)

Model | Dimension (Фmm) | Sensitivity | air compression | Max.throughput(L/h) | Material temperature | Defectives eliminated time | Installation height(mm) | |

FeΦ | SUSΦ | |||||||

PEC2005B-30 | 30 | 0.2mm | 0.4mm | 3~5Bar | 400 | < 80℃ | 0.3~5s | |

PEC2005B-50 | 50 | 0.3mm | 0.6mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s | |

PEC2005B-70 | 70 | 0.7mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s | |

PEC2005B-100 | 100 | 0.8mm | 1.2mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s | 473 |

PEC2005B-120 | 120 | 1.0mm | 1.5mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s | |

PEC2005B-150 | 150 | 1.2mm | 2.0mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s | 600 |

PEC2005B-200 | 200 | 2.0mm | 2.5mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s | 922 |

PEC2005B-250 | 250 | 3.0mm | 3.5mm | 3~5Bar | 69000 | < 80℃ | 0.3~5s | 948 |