+86 15814116500

+86 15814116500 | Availability: | |

|---|---|

| Quantity: | |

AEC500C

COSO

Product Description

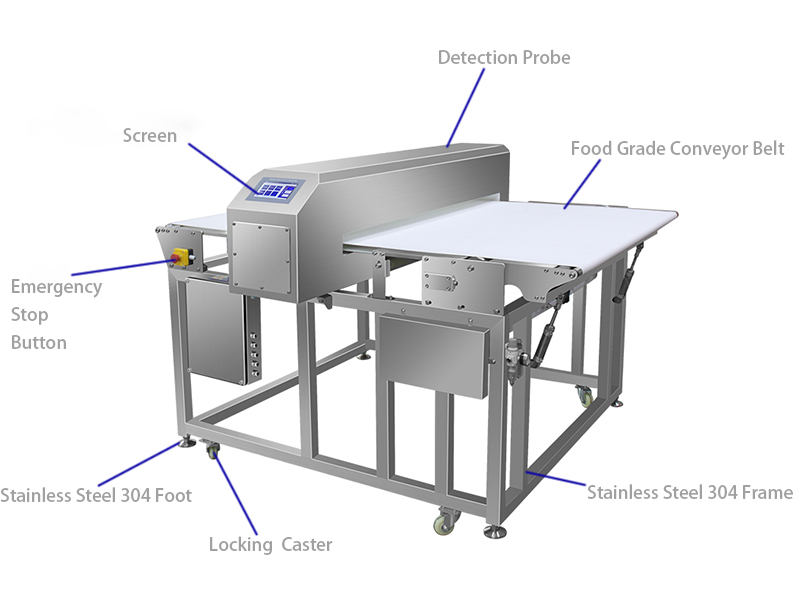

COSO’s conveyor metal detector is designed to detect metallic contaminates in baked goods, cookies, biscuits, muffins, donuts, and cupcakes. Whether your production lines handles delicate pastries or bulk-baked goods, our metal detector can detect metal contaminates like ferrous, steel stainless to help you reduce the risk of costly recalls and maintain consumer trust. COSO metal detector can meet standards to offer reliable detection and protect your brand reputation.

Product Video: Professional Bakery Metal Detector for Biscuits & Cookies

This video demonstrates the COSO industrial metal detector specifically designed for bakery production lines. Biscuits and cookies require high-precision inspection to ensure no metallic fragments from processing machinery enter the final packaging.

Product Application

Field Application

Product Features

This machine features a seamless transmission structure, enabling efficient integration into the production line and ensure continuous, uninterrupted workflow.

It features small bearings with strong clamping force, effectively securing the belt and preventing slip.

It can be fitted with a customizable ultra-wide belt and an adjustable detection height to handle a variety of products.

The detection probe is positioned closer to the product, significantly improving detection sensitivity.

Equipped with an automatic belt alignment function, it supports stable transmission, making it suitable for production line.

It has self-learning funciton and can store 200 sets of product parameters.

Belt sinking: Quick action reduces the rejection time, preventing products jams.

Flap rejection: It suitable for end stations or scenarios where the downstream conveyor belt height is lower than the upstream, enabling smooth integration.

Product Details

Optional Rejection

Belting Sinking Rejection

Flap Rejection

Check information of this product

Product Description

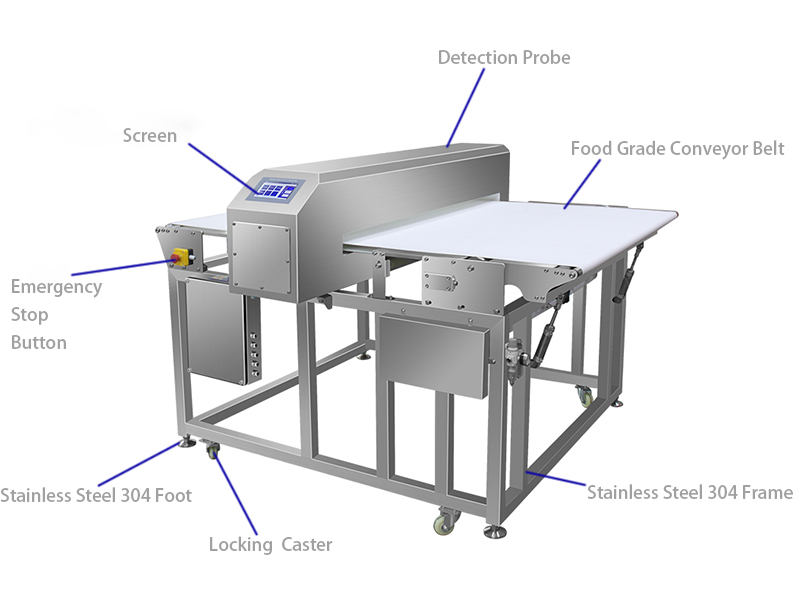

COSO’s conveyor metal detector is designed to detect metallic contaminates in baked goods, cookies, biscuits, muffins, donuts, and cupcakes. Whether your production lines handles delicate pastries or bulk-baked goods, our metal detector can detect metal contaminates like ferrous, steel stainless to help you reduce the risk of costly recalls and maintain consumer trust. COSO metal detector can meet standards to offer reliable detection and protect your brand reputation.

Product Video: Professional Bakery Metal Detector for Biscuits & Cookies

This video demonstrates the COSO industrial metal detector specifically designed for bakery production lines. Biscuits and cookies require high-precision inspection to ensure no metallic fragments from processing machinery enter the final packaging.

Product Application

Field Application

Product Features

This machine features a seamless transmission structure, enabling efficient integration into the production line and ensure continuous, uninterrupted workflow.

It features small bearings with strong clamping force, effectively securing the belt and preventing slip.

It can be fitted with a customizable ultra-wide belt and an adjustable detection height to handle a variety of products.

The detection probe is positioned closer to the product, significantly improving detection sensitivity.

Equipped with an automatic belt alignment function, it supports stable transmission, making it suitable for production line.

It has self-learning funciton and can store 200 sets of product parameters.

Belt sinking: Quick action reduces the rejection time, preventing products jams.

Flap rejection: It suitable for end stations or scenarios where the downstream conveyor belt height is lower than the upstream, enabling smooth integration.

Product Details

Optional Rejection

Belting Sinking Rejection

Flap Rejection

Check information of this product